The construction industry has long been known for its relentless pursuit of materials that offer a unique blend of durability, performance, and lightness. In this pursuit, we find the innovative applications of polyurethane foam blocks and PU foam sheets. These materials have become a go-to solution for various construction needs. This article will explore why and how these lightweight materials make waves in construction.

The construction industry has long been known for its relentless pursuit of materials that offer a unique blend of durability, performance, and lightness. In this pursuit, we find the innovative applications of polyurethane foam blocks and PU foam sheets. These materials have become a go-to solution for various construction needs. This article will explore why and how these lightweight materials make waves in construction.

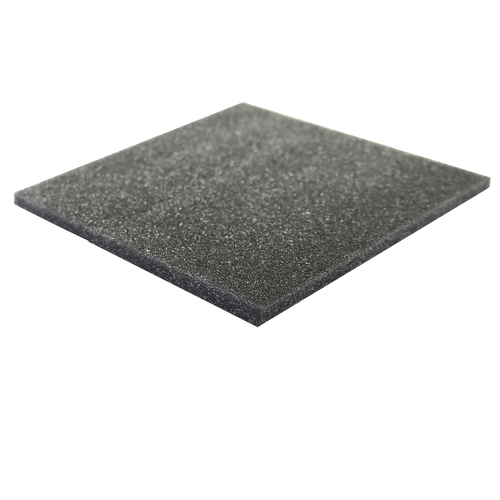

Why Choose PU Foam Sheets in Construction?

Energy Efficiency:

- Polyurethane foam blocks and PU foam sheets are excellent insulators. They have tiny air pockets that trap heat, providing thermal resistance. In construction, this translates to less heat escaping in the winter and less heat entering in the summer.

- By maintaining a stable temperature inside the building, these materials contribute to significantly reduced heating and cooling costs. This lowers energy bills and promotes a greener environment by reducing energy consumption.

Durability:

- The inherent strength of polyurethane foam blocks comes from their cellular structure and chemical composition. They resist deformation, wear, and degradation from environmental factors.

- The long-lasting nature of these materials ensures they can endure the stresses and strains of construction without compromising structural integrity. This saves on replacement and maintenance costs in the long run.

Ease of Application:

- Polyurethane foam blocks are easy to shape, cut, and apply. Thanks to their flexibility, they can be used in various ways, such as insulation panels or structural components.

- This adaptability allows for a broader range of applications within the construction industry. It means quicker installation times, less labor, and a more streamlined construction process, which can lead to cost savings.

How Are PU Sheet Suppliers Innovating the Industry?

Customization

- Many Pu sheet suppliers, including TCH, offer tailored solutions. They can produce sheets and blocks in specific sizes, shapes, and densities to match a project’s needs.

- Customization enables more precise usage and less waste, ensuring the materials fit seamlessly into the project, enhancing efficiency and aesthetics.

Environmental Considerations:

- Suppliers increasingly focus on sustainability using eco-friendly production methods or recycled materials in polyurethane foam blocks.

- This aligns with the global push for more environmentally friendly construction practices, helping projects meet sustainability goals without sacrificing performance or affordability.

Collaboration with Construction Experts:

- By working directly with architects, builders, and engineers, suppliers can understand the unique requirements of each project and offer solutions that fit those specific needs.

- Such collaboration fosters innovation and ensures that the products supplied are not only of high quality but are also the best fit for the particular application, leading to higher satisfaction and success in construction project

What Projects Can Benefit from Polyurethane Foam Blocks?

Almost any construction project can leverage the benefits of these lightweight materials. Here's a closer look at where they shine:

Roofing Insulation:

- Creating a Thermal Barrier: Polyurethane foam blocks form an exceptional thermal barrier when roofing.

- How It Works: By filling gaps, seams, and cracks, these foam blocks prevent heat transfer between the external environment and the interior of the building.

- Why It Matters: This helps maintain internal temperatures at a desired level, resulting in greater energy efficiency. The consequent savings on heating and cooling costs and the comfort of a well-regulated indoor climate make this application highly attractive for residential and commercial projects.

Wall Construction:

- Structural or Non-Structural Component: Polyurethane foam blocks can be used as integral structural components or as non-structural additions in wall construction.

- How It Works: These blocks contribute to the wall's overall strength as a structural component. As non-structural components, they offer insulation and aesthetic benefits. Their lightweight nature and ease of installation make them a convenient choice for rapid construction.

- Why It Matters: Whether enhancing the load-bearing capacity of a wall or simply providing an insulating layer, polyurethane foam blocks add versatility and efficiency to wall construction. They cater to various construction needs, from residential homes to large commercial buildings.

Industrial Insulation:

- Offering Protection: In industrial settings, polyurethane foam blocks are valuable insulation against various environmental factors such as temperature.

- How It Works: These blocks can be applied to machinery, pipes, and walls, which act as barriers to thermal fluctuations, noise pollution, and mechanical vibrations.

- Why It Matters: Using polyurethane foam blocks in industrial insulation enhances the working conditions for employees by minimizing noise and temperature extremes. It also protects sensitive equipment from harmful vibrations and temperature changes, thereby prolonging the life of the machinery and reducing maintenance costs.

Strategies for Selecting the Right PU Foam Sheets

- Understand Your Needs: Determine the specific requirements of your construction project, considering factors such as specifications, budget, and unique needs.

- Engage with Reputable Suppliers: Choose PU sheet suppliers with a strong track record in delivering quality products, like TCH, and don't hesitate to ask for samples.

- Consider Environmental Impact: Opt for materials that align with sustainability goals, including eco-friendly options, alignment with standards, and long-term impact.

- Evaluate Technical Support and Services: Look for suppliers that offer consultation, customization, installation guidance, and post-purchase support to ensure a successful project.

Conclusion

Integrating polyurethane foam blocks into modern construction is more than a trend; it’s a logical evolution. The benefits of using pu foam sheets are profound, from energy efficiency to adaptability.

At TCH, we pride ourselves on offering these cutting-edge solutions. We work closely with you to ensure the right fit for your project, and our commitment to quality makes us one of the leading pu sheet suppliers in the industry. Explore our range of products and discover how we can be part of your next innovative construction project.